B3002 Series

Product Description

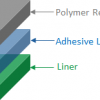

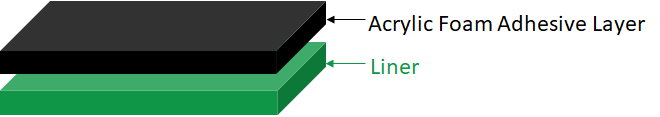

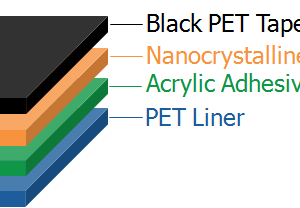

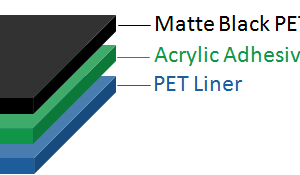

B3002 Series tape features a specially structured black acrylic foam layer and is waterproof. The special structure can provide superior impact resistance to meet drop and puncture testing as well as excellent die-cutting performance.

Features

✔ High Bond Strength

✔ Waterproof

✔ Easy Die-Cut

✔ RoHS Compliant & Halogen Free

Applications

B3002 Series tape can be used in a wide range of electronic components bonding such as lens bonding and LCM attachment along with other bonding applications where impact resistance, high strength and waterproof bonding are needed.

Typical Properties

| Part Number | B3002-010 | B3002-015 | B3002-020 | B3002-025 | B3002-030 | B3002-040 | B3002-050 | B3002-060 | B3002-080 | B3002-110 | Test Method |

| Available Thickness (mm) | 0.10 | 0.15 | 0.20 | 0.25 | 0.30 | 0.40 | 0.50 | 0.64 | 0.80 | 1.10 | ASTM D3652 |

| Color | Black | – | |||||||||

| Foam Density (kg/m3) | 920 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | ASTM D1622 |

| Type of adhesive | Acrylic-based | – | |||||||||

| 900 Peel to SUS (kg/inch @72hrs RT) | 2.8 | 4.0 | 4.0 | 4.5 | 4.5 | 5.8 | 6.0 | 5.9 | 8.0 | 10.6 | ASTM D3330 |

| Static Shear (1.5kg, 22℃) | ≥168hr | ASTM D3654 | |||||||||

| Dynamic Shear (kg/inch2) | 49.5 | 64.5 | 64.5 | 64.5 | 64.5 | 64.5 | 64.5 | 64.5 | 72.5 | 72.5 | Internal |

| Waterproof Class | IPX 8 | – | |||||||||

| Operating Temperature (°C) | -40~120 | – | |||||||||

| Standard Size (mm x m) | 800*33/66 | – | |||||||||